About Thaai Casting Limited

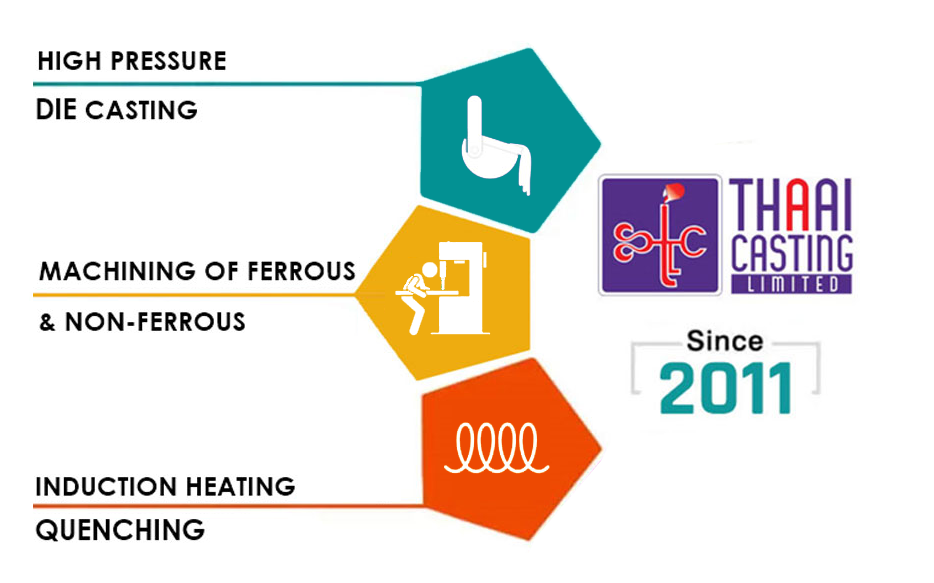

We are a distinguished automotive ancillary company with IATF 16949:2016 certification, specializing in HighPressure Die Casting, as well as the precision Machining of both Ferrous and Non-Ferrous materials and Induction heating and quenching. Founded by Mr. Sriramulu Anandan, a seasoned professional with extensive expertise in Pressure Die Casting and Machining Processes, our business model is firmly rooted in a B2B approach, catering to leading entities in the automotive components sector. Our product portfolio encompasses a diverse range of Automobile components, including Engine Mounting Support Brackets, Transmission Mounts, Fork Shift and Housing, Armature – Steering Wheel, Electrical Connectors, YFG Base Frame (Right-hand drive side/Left-hand drive side), Housing, Top Cover, and more.

In recognition of our commitment to environmental sustainability, we proudly received the MSIL-GREEN Certification from Maruti Suzuki India Limited in 2021. This acknowledgment underscores our dedication to adopting and promoting eco-friendly practices within our operations. In 2022, our company was honoured with prestigious awards from industry leaders such as Hanon and RSB, recognizing our excellence in terms of Best Quality and being a standout Vendor. As we continue to evolve and uphold the highest standards in our manufacturing processes, we remain steadfast in delivering top-notch products and services to our valued clientele in the automotive sector.

Mission & Vision

THAAI CASTING LIMITED mission and vision is to set a benchmark in Quality Leadership. We Deliver Quality Moulds in much shorter lead time of manufacturing as required from your conceptual thoughts & Design.

- Maintain our Reputation as a Reliable Source for Quality Die Cast & Machined Products.

Quality Policy

THAAI CASTINGS LIMITED is Totally Committed to Achieve Customers Satisfaction by following QCDS Principles.

- THAAI CASTING LIMITED will achieve this by establishing, maintaining and continually improving the effectiveness of our QMS.

- We will strive for excellence through dedicated team work and total employees involvement.

Managing Director

Founder Mr. S. ANANDAN

Experience – 3.0 Decades

Qualification

- DPMT, PD PMD

- Polimer Technology in WASEDA University – JAPAN

- In Plant Training in Yonimochi Mould Making in Japan (1 YR)

Mr. S. Anandan has more than three decades of rich experience in Pressure Die Casting & Machining Process

Our Team

Mr. VENKATESAN

Director

Ms. SHEVAANI

Director

Mr. RAMAKRISHNAN

Director

Mr. NAREN KUMAR

Independent Director

Mr. KUMARASWAMY

Independent Director

Mr. GAUTHAM

Independent Director

Mr. PRAVEEN RAJ

Operations – Head

Mr. SENTHAMARAI KANNAN

Heat Treatment – Head

Mr. MANOHAR

HR Manager